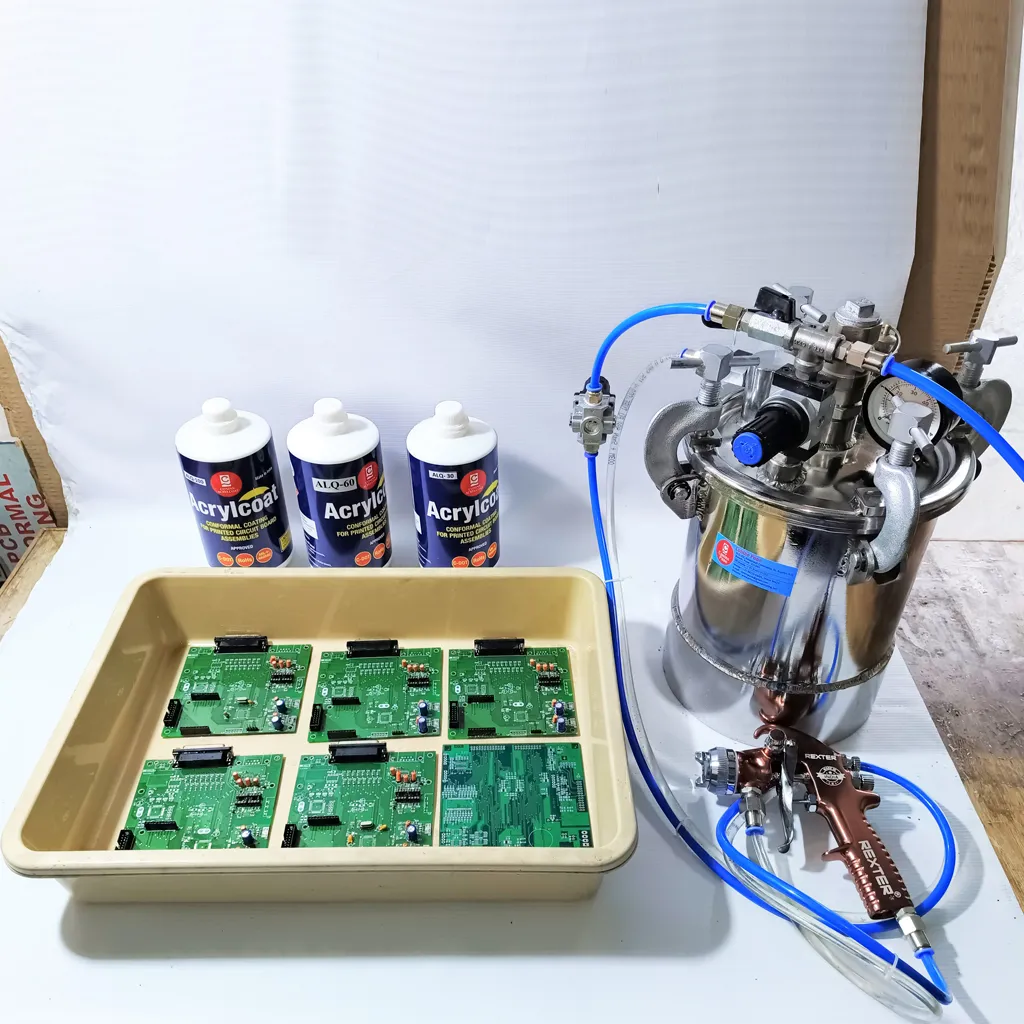

When the production of PCB Assembly. is in quantity the external pump with spray gun & compressed air is used. This is having 1no air tight cylinder where 5 Liters of ACRYLCOAT is placed connected with a tube and valve.

Then mixing of compressed air and Acrylcoat lacquer in proper combination and air pressure and adjusting the spray nozzle we can spray Acrylcoat to quantity of PCB Assembly. at a time.

Place the PCB Assembly. On the table with coating surface upside in a line close to each other , Adjust the Spray through and air pressure as require. hold the spray gun in the angle required and start spraying uniformly and steadily.

The coating will get spread on surface when it is in liquid stage.

Only ALQ -30 ,ALQ 60 & ALQ-100 can be spray by this method.

Once the spraying is over and going to stop for a day, Cleaning of container by ELCLEAN with the tube & spray gun to be done.

Let the all boards get touch to dry then only lift it and start further process.

For faster drying preheating and post heating procedure can adopted.

Continuity test after coating to be done only after 4-6 Hrs

Avoid flames and sparks nearby process.

How to make fast coating for bulk quantity PCB assembly.

Pre Heat & Post Heat procedure

For preheat & posts heating drying process use of Hot Air blower or Oven or 100 watt bulb cavity can be arrange but it should be open type to vapor the solvents in AIR

| PRODUCT CODE | ACRYLCOAT - LED - LGT - SPL - 60 |

|---|---|

| PRODUCT CODE | Acrylcoat - LED-LGT-SPL-60 |

| Appearance (Liquid & Coated Film) | Clear / Transparent / Smooth & Glossy |

| Specific Gravity (Density @25°C) | 0.85 to 0.91 |

| Viscosity @25°C | 60 - 65 sec (Zans Cup #2) |

| Flash Point | < 79°C |

| Comparative Tracking Index (CTI Value) | 600 |

| Coating Thickness (Single Coat) | 30 - 35 μm Recommended |

| Dielectric Strength | 25 KV/mm |

| Thermal Cycling (MIL-I-46058-C-AR) | Passes as per MIL-STD |

| Moisture Resistance (MIL-I-46058-C-AR) | Passes as per MIL-STD |

| Insulation Resistance (MIL-I-46058-C-AR) | Passes as per MIL-STD |

| Fungus Resistance (MIL-I-46058-C-AR) | Passes as per MIL-STD |

| Withstand Temperature (Film) | -50 to 130°C |

| Coverage Area (20 μm Film – 500 ml Aerosol) | 5 - 6 m² |

| Film Traceable | With Eye |

| Drying Time (Touch to Dry) | 8 - 10 Min @ Room Temp. |

| Hard Dry | 2 Hrs @ Room Temp. |

| Pre Heating of PCB @50°C (Touch to Dry) | 2 - 3 Min |

| Post Heating of PCB @50°C (Hard Dry) | 5 - 10 Min |

| Curing Time | 12 - 24 Hrs |

| Optimum Properties | 7 Days |

| Packing | 1, 5, 25 Litre |

Store in a cool dry place below 40oC. Keep away from naked flame or flammable material. The contents are highly inflammable. Destroy the container after use.